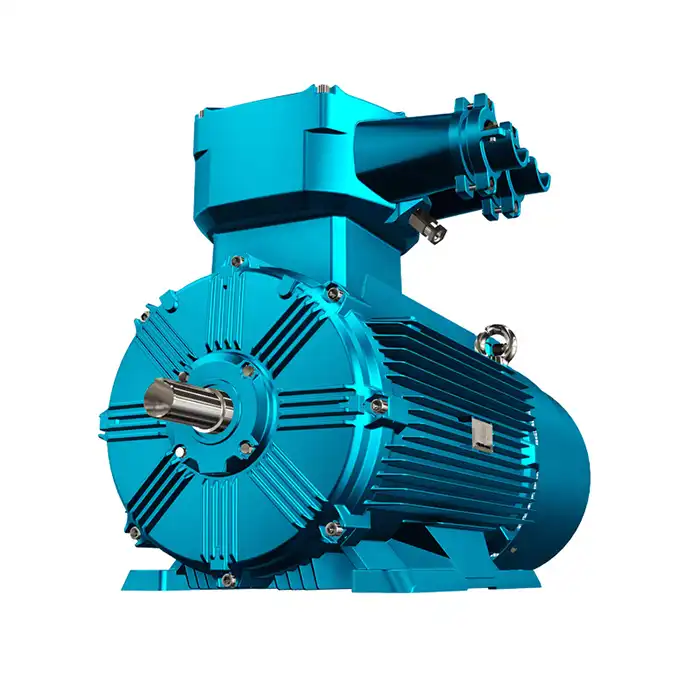

exde motor

Voltage range:380V,660V,415V,380/660V,660/1140V

Power range:0.55-355 kW

Application:places where explosive gas mixtures exist in petroleum, chemical, mining, metallurgy, electric power, machinery and other industries.

Advantage: wide speed regulation range, fast dynamic response, high speed regulation accuracy.

Explosion-proof mark: Ex d I Mb, Ex d IIB T4 Gb, Ex d IIC T4 Gb

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Exde Motor Manufacturer and Supplier

Welcome to Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., your trusted exde motor manufacturer and supplier. With over two decades of experience, we've perfected our products to deliver unparalleled performance, energy efficiency, and reliability. Our partnerships with global industry leaders ensure you receive cutting-edge technology tailored to your needs.

Exde Motor Description

XCMOTOR's products are crafted with a clear aim to revolutionize your power equipment solutions. Our robust exde motors seamlessly blend advanced technology with unrivaled durability. This unique combination makes them suitable for an extensive array of industrial applications, from heavy - duty manufacturing processes to precision - based operations. Whether you're planning to upgrade your existing system for enhanced efficiency or embarking on a new project, our products stand out as the perfect choice. They not only promise high performance but also significant energy savings, ensuring long - term cost - effectiveness and environmental friendliness.

YBBP Product Specifications

| Power range: | 0.55kW to 355kW |

| Voltage: | 380V,660V,415V,380/660V,660/1140V |

| Frequency: | 50Hz |

| Protection class: | IP55 (higher protection available) |

| Insulation class: | F (class H optional) |

Product Details

Our exde motors feature:

- Our motors are equipped with premium copper windings. The high - purity copper ensures enhanced conductivity, allowing for efficient power transfer and improved performance.

- High - grade silicon steel laminations are utilized to minimize core losses. This design reduces energy waste and contributes to overall motor efficiency.

- Precision - balanced rotors play a crucial role. They are carefully engineered to guarantee smooth operation, minimizing vibrations and noise during use.

- Robust bearings are installed to extend the motor's lifespan. These bearings can withstand heavy loads and continuous operation with minimal wear.

- An advanced cooling system is incorporated for optimal temperature control. It effectively dissipates heat, preventing overheating and ensuring reliable motor performance.

Production Process

- Core stamping and stacking involve precision - cutting steel sheets into core shapes and carefully stacking them to form a stable magnetic core for motors.

- Winding and insertion is a meticulous process where copper wires are wound around the core and precisely inserted to enable efficient electrical - magnetic energy conversion.

- Varnish impregnation coats the wound components with a protective varnish. This not only insulates but also strengthens the windings, enhancing durability.

- Rotor balancing ensures smooth operation. Specialized equipment is used to detect and correct any imbalances in the rotor, reducing vibrations.

- Assembly and testing bring all components together. Thorough tests are then conducted to guarantee the final product meets quality and performance standards.

Application Scenarios

XCMOTOR's products excel in various industries:

- Manufacturing plants

- Water treatment facilities

- Mining operations

- Oil and gas refineries

Certifications

Our exde motors meet international standards:

- CE certified

- CCC approved

- ISO 9001:2015 quality management system

Why Choose XCMOTOR?

- With over 20 years in motor manufacturing, we've amassed profound industry expertise, understanding every nuance of motor design and production.

- Our quality assurance is top - notch. We employ rigorous testing and strict quality control procedures at every production stage to ensure product excellence.

- We offer custom solutions. Our team crafts tailored motors, precisely matching your unique requirements, be it power output or size constraints.

- Our global support is comprehensive. From pre - sales advice to after - sales service, we're there for you worldwide, ensuring seamless customer experience.

- We prioritize energy efficiency. Our motors are designed to cut operating costs and minimize environmental impact through optimized energy use.

Frequently Asked Questions

Q: What makes XCMOTOR's products different from standard motors?

A: Our products are designed for superior efficiency, reliability, and performance. They feature advanced materials and construction techniques that result in lower energy consumption and longer lifespan compared to standard motors.

Q: Can I get a customized product for my specific application?

A: Absolutely! We specialize in creating tailored solutions. Contact our team, and we'll work with you to design an product that perfectly fits your requirements.

Q: What is the warranty on XCMOTOR's products?

A: We offer a standard 12-month warranty on all our products, reflecting our confidence in their quality and durability.

Contact us

Ready to upgrade your power equipment with XCMOTOR's exde motors? Contact us today at xcmotors@163.com to discuss your needs and discover how we can help you achieve optimal performance and energy efficiency in your operations.