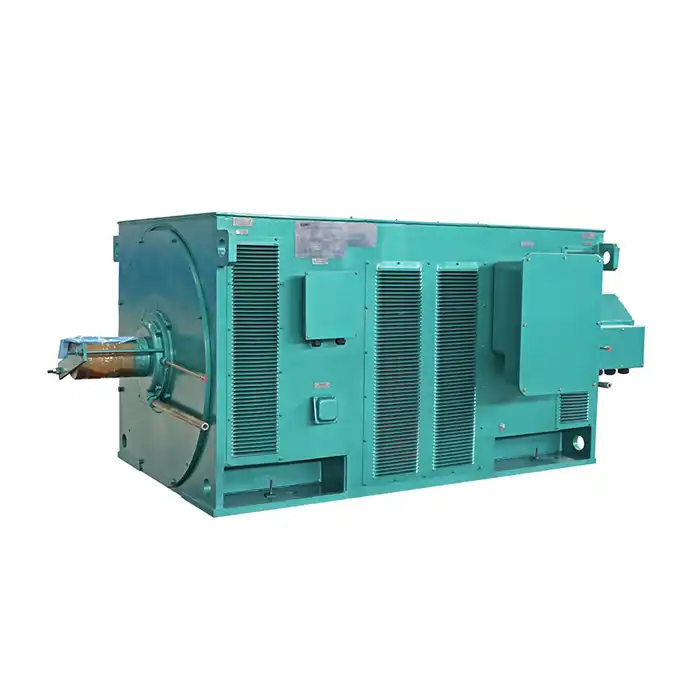

most energy efficient motor

Protection level:IP23

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:220-3550 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:high efficiency and energy saving, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies with JB/T 12728 and JB/T 10446 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Your Trusted Most Energy Efficient Motor Manufacturer and Supplier

At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we take pride in manufacturing and supplying the most energy efficient motors in the industry. Our cutting-edge technology, coupled with decades of experience, allows us to deliver superior performance while minimizing energy consumption. Choose XCMOTOR for unparalleled efficiency, reliability, and long-term cost savings.

Most Energy Efficient Motor Description

Our state-of-the-art most energy efficient motors are designed to maximize vitality productivity whereas keeping up remarkable control and execution. Planned with progressed innovation, these high-efficiency engines offer assistance businesses diminish vitality utilization, driving to critical taken a toll investment funds. They are perfect for companies looking to lower their carbon impression, as they advance maintainability without relinquishing execution. With their strong development and optimized plan, our engines provide solid and long-lasting operation, making them the culminate choice for businesses looking for both natural and financial benefits.

YX Product Specifications:

| Power Range: | 220 kW to 3550 kW |

| Voltage: | 3000V~11000V |

| Frequency: | 50 Hz |

| Efficiency Class: | IE3 |

| Protection Class: | IP55 |

Product Details:

Product Details:

Our most energy efficient motors feature:

- Our motors feature an advanced magnetic core design, enhancing efficiency and reducing energy loss for superior performance and longevity.

- The use of high-quality copper windings ensures maximum conductivity, improving overall energy efficiency and reducing heat generation during operation.

- Precision-balanced rotors are carefully engineered to reduce vibration and noise, ensuring smooth and stable motor performance in demanding applications.

- An optimized cooling system is integrated into the motor design, effectively dissipating heat and maintaining optimal temperature for reliable operation.

- Low-friction bearings minimize mechanical resistance, reducing wear and tear, ensuring long-term durability and improving overall motor efficiency.

Technical Data:

| Efficiency: | Up to 96.8% (size-dependent) |

| Power Factor: | 0.85-0.89 |

| Insulation Class: | F (155°C) |

| Temperature Rise Class: | B (80K) |

| Ambient Temperature: | -20°C to +40°C |

Production Process:

- Design and simulation involve creating detailed models using advanced software to optimize motor performance, efficiency, and reliability before production begins.

- Raw material selection focuses on choosing premium components, such as high-grade metals and insulators, to ensure durability, performance, and efficiency in the final product.

- Stator and rotor assembly requires precision engineering to ensure perfect alignment, reducing energy loss, vibration, and ensuring smooth and reliable motor operation.

- Winding and impregnation processes are critical to ensuring the motor's electrical efficiency, insulating wires, and preventing overheating or potential failures during operation.

- Final assembly involves combining all components into a fully functional motor, ensuring correct placement and connection for optimal performance and reliability.

- Testing and quality control are conducted thoroughly to verify each motor meets performance standards, ensuring it functions efficiently, safely, and reliably in real-world applications.

Application Scenarios:

- Industrial machinery

- HVAC systems

- Pumps and compressors

- Conveyor systems

- Renewable energy installations

Why Choose XCMOTOR?

- Our motors exceed IE4 efficiency standards, ensuring maximum energy savings while reducing operational costs and supporting sustainability goals.

- We offer a wide range of customization options to meet your specific needs, ensuring the perfect fit for your industrial applications.

- With over 20 years of experience in motor manufacturing, we deliver products renowned for their reliability, durability, and long-lasting performance.

- Our comprehensive support includes pre-sales consultation and after-sales service, ensuring you receive continuous assistance and guidance throughout the product lifecycle.

- We form global partnerships with leading brands like ABB and Siemens, bringing you the latest technology and the highest quality motors.

FAQ:

FAQ:

Q: How much can I save by switching to your products?

A: Savings vary depending on usage, but many customers report 20-30% reduction in energy costs.

Q: Are these motors compatible with variable frequency drives (VFDs)?

A: Yes, our motors are designed to work seamlessly with VFDs for even greater efficiency.

Q: What's the payback period for investing in your high-efficiency motors?

A: Typically, customers see a return on investment within 12-24 months, depending on operating conditions.

Q: Do you offer warranties on your products?

A: Yes, we provide a standard 1-year warranty, with extended options available.

Q: Can these motors be used in harsh environments?

A: Absolutely. We offer IP55 and higher protection classes for challenging conditions.

Contact us

Ready to boost your energy efficiency and reduce operational costs? Contact us today at xcmotors@163.com to learn how our most energy efficient motors can transform your business. Let's power a greener future together!