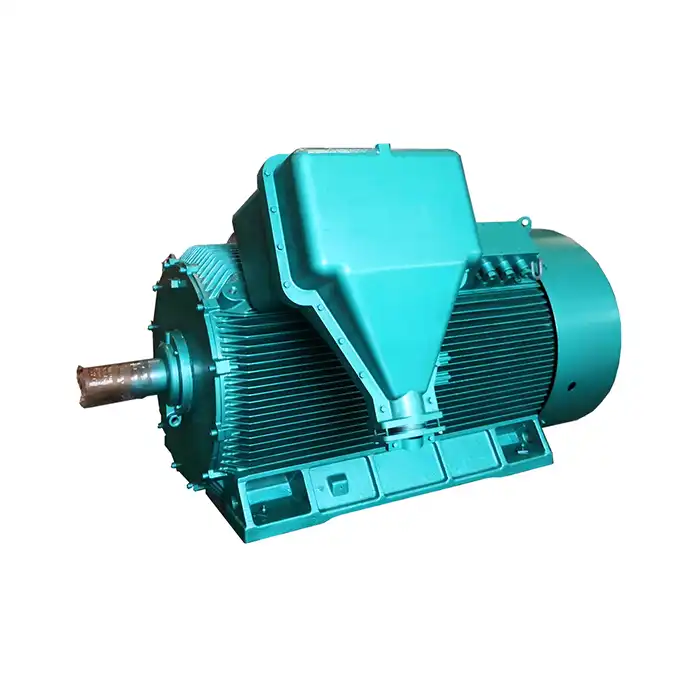

5kv motor

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:160-1600 kW

Application:fans, water pumps, compressors, crushers, cutting machine tools, transportation machinery, etc.

Advantage:compact structure, light weight, low noise, small vibration, long service life, easy installation and maintenance.

Standard: This series of products complies withJB/T10444-2004 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Your Trusted 5kV Motor Manufacturer and Supplier

As a leading 5kV motor manufacturer and supplier, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers superior quality and reliability. Our products boast high energy efficiency, low maintenance requirements, and exceptional performance in diverse industrial applications.

5kV Motor Description

Our 5kV motors are meticulously designed to meet the demanding requirements of modern industrial operations. These robust, high-efficiency motors deliver consistent and reliable power output while optimizing energy consumption for maximum operational savings. Built to perform in extreme conditions, they are ideal for industries such as mining, oil and gas, and manufacturing, where durability and reliability are essential. With advanced engineering and quality construction, our products excel in challenging environments, ensuring long-lasting performance and minimal downtime.

Y2 Product Specifications

| Voltage Rating: | 3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5% |

| Power Range: | 160kW to 1600kW |

| Frequency: | 50Hz |

| Insulation Class: | F/H |

| Protection Class: | IP55 (Higher available upon request) |

Product Details

Our 5kV motors feature:

- High-quality copper windings are used in our motors, ensuring enhanced efficiency and reduced energy losses for improved performance.

- Precision-balanced rotors are incorporated to ensure smooth operation, minimizing vibrations and optimizing motor stability for long-term reliability.

- Robust bearings are designed for extended service life, providing superior durability and reducing maintenance needs, even in demanding environments.

- Advanced thermal management systems are integrated to maintain optimal operating temperatures, preventing overheating and ensuring consistent motor performance in harsh conditions.

Production Process

- Design and Engineering involves creating innovative motor solutions, ensuring optimal performance, durability, and efficiency for industrial applications.

- Raw Material Procurement focuses on sourcing high-quality materials, such as copper, steel, and insulation, to meet strict performance standards.

- Stator and Rotor Assembly is the process of meticulously assembling these critical components, ensuring proper alignment and balance for smooth motor operation.

- Winding and Insulation involves precision winding of copper coils and applying high-quality insulation materials to prevent short circuits and enhance durability.

- Final Assembly includes integrating all components into a complete motor system, ensuring proper functionality and seamless operation across all parts.

- Testing and Quality Control rigorously checks each motor's performance, safety, and reliability through extensive testing to meet industry standards.

Application Scenarios

Our 5kV motors are ideal for:

- Mining operations

- Oil and gas facilities

- Power generation plants

- Large industrial pumps and compressors

- Paper and pulp mills

Why Choose XCMOTOR?

- With over 20 a long time of involvement in engine fabricating, we have built a demonstrated track record of conveying solid, high-quality products

- We guarantee quality affirmation through solid organizations with driving brands like ABB and Siemens, guaranteeing top-notch components and performance.

- Our engines offer customization, giving custom fitted arrangements outlined to meet your particular necessities, optimizing execution and effectiveness for your needs.

- We offer comprehensive back, giving master pre-sales and after-sales benefit to help with choice, establishment, and long-term maintenance.

- Our energy-efficient engines are planned to diminish operational costs by maximizing execution whereas minimizing vitality utilization, advertising long-term reserve funds.

Frequently Asked Questions

Frequently Asked Questions

Q: What's the typical lead time for a product?

A: Standard models are usually available within 6-8 weeks. Custom designs may take 10-12 weeks.

Q: Do you offer installation services?

A: Yes, we provide installation and commissioning services to ensure optimal performance.

Q: How often should a product be serviced?

A: We recommend a thorough inspection every 12-18 months, depending on the operating conditions.

Q: Can your products be retrofitted into existing systems?

A: Absolutely. Our team can assess your current setup and provide a tailored solution.

Q: What warranty do you offer on products?

A: We provide a standard 12-month warranty, with extended options available.

Contact us

At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we're committed to powering your success with our high-performance 5kV motors. Our team of experts is ready to assist you in selecting the perfect motor for your application. Contact us today at xcmotors@163.com to discuss your power equipment needs and experience the XCMOTOR difference.