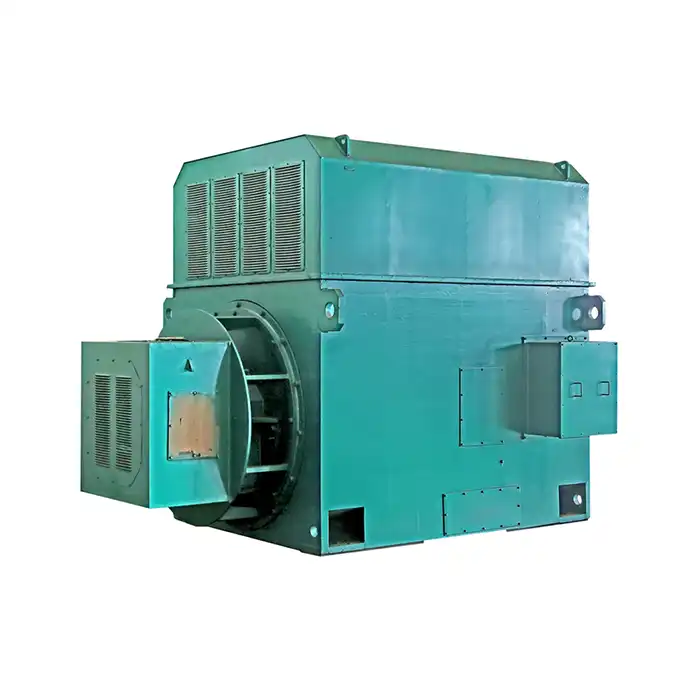

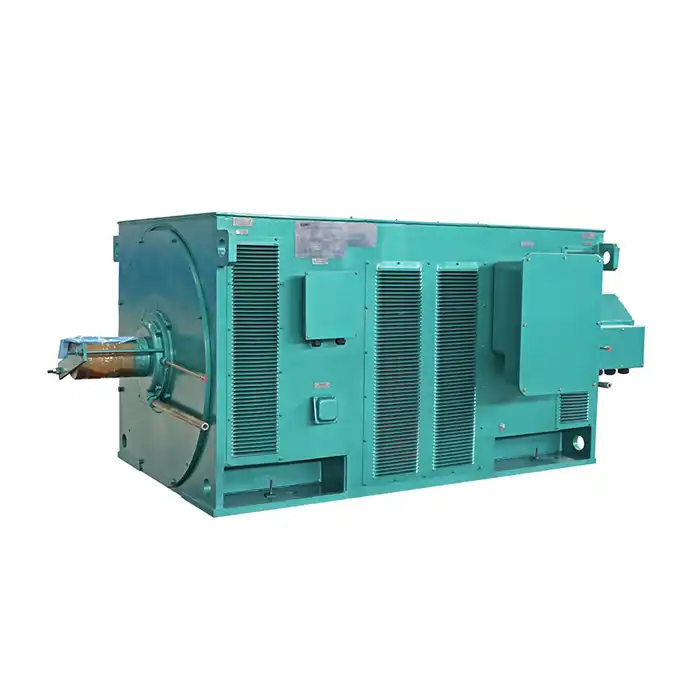

yrkk motor

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

YRKK Motor Manufacturer and Supplier

Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. is a leading YRKK motor manufacturer and supplier. With over two decades of experience, we pride ourselves on delivering top-quality products that offer exceptional energy efficiency, reliability, and performance. Our commitment to innovation and customer satisfaction sets us apart in the industry.

YRKK Motor Description

Our YRKK motors are meticulously engineered to meet the rigorous demands of modern industrial applications. These high-performance motors are crafted using advanced technology and superior materials, ensuring optimal efficiency and reliability. With a focus on robustness, they are built to withstand challenging environments and perform consistently under heavy loads. Whether used in manufacturing, HVAC systems, or other industrial sectors, our motors provide long-lasting performance, reducing downtime and maintenance costs while ensuring smooth and efficient operation across diverse applications.

Product Specifications:

| Power range: | 200kW to 4500kW |

| Voltage: | 3000V,3300V,6000V,6600V,10000V,11000V |

| Frequency: | 50Hz |

| Protection class: | IP54/IP55 |

| Insulation class: | F (standard), H (optional) |

Product Details:

Product Details:

YRKK motors feature a unique design that incorporates:

- Copper rotor bars for enhanced efficiency

- High-quality silicon steel laminations to reduce core losses

- Optimized cooling system for improved heat dissipation

- Reinforced bearing system for extended service life

Production Process:

Our products undergo a rigorous manufacturing process, including:

- Precision Die-Casting of Rotor: Our rotors are crafted using precision die-casting techniques, ensuring high-quality, accurate components that enhance performance and reliability.

- Advanced Winding Techniques: We employ advanced winding techniques that improve the efficiency and durability of our motors, ensuring optimal power delivery and longevity.

- Vacuum Pressure Impregnation (VPI) for Superior Insulation: Our motors feature vacuum pressure impregnation (VPI) technology, providing superior insulation that enhances performance and protects against environmental factors.

- Comprehensive Testing and Quality Control: Each motor undergoes comprehensive testing and stringent quality control measures to ensure it meets industry standards and delivers exceptional performance and reliability.

Application Scenarios:

The products excel in various industrial applications, such as:

- Pumps and compressors

- Fans and blowers

- Conveyor systems

- Machine tools

- Mining equipment

Certifications:

Our products comply with international standards and hold certifications including:

- CE

- CCC

Why Choose XCMOTOR?

- Broad Encounter in Engine Fabricating: With a long time of industry encounter, we have aced the craftsmanship of engine fabricating, conveying high-quality, solid engines custom fitted to your needs.

- Customization Choices to Meet Particular Necessities: We give a wide run of customization alternatives, guaranteeing each engine is superbly suited to your one of a kind operational necessities and specifications.

- Comprehensive Specialized Bolster and After-Sales Benefit: Our master group offers nonstop specialized back and after-sales benefit, guaranteeing consistent operation and tending to any concerns expeditiously for your satisfaction.

- Competitive Estimating Without Compromising Quality: We offer competitive estimating, keeping up high-quality measures in each engine created, giving uncommon esteem for your speculation without relinquishing performance.

- Quick Turnaround Times and Dependable Conveyance: We guarantee quick generation and solid conveyance, assembly due dates and guaranteeing your operations run easily without delays, keeping your ventures on track.

Frequently Asked Questions:

Q: What is the warranty period for the products?

A: We offer a standard 12-month warranty on all our products, with extended warranty options available.

Q: Can products be used with variable frequency drives (VFDs)?

A: Yes, our products are designed to be compatible with VFDs for enhanced speed control and energy savings.

Q: What is the typical lead time for the product orders?

A: Standard models are usually available within 2-4 weeks, while customized solutions may take 4-6 weeks.

Q: Do you offer installation and commissioning services?

A: Yes, we provide comprehensive installation and commissioning services to ensure optimal performance of your products.

Q: Are spare parts readily available for the products?

A: We maintain a well-stocked inventory of spare parts and can quickly supply any components you may need for maintenance or repairs.

Contact us

At Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd., we're committed to providing you with high-quality YRKK motors that meet your specific needs. Our team of experts is always ready to assist you in selecting the right motor for your application and ensuring its optimal performance throughout its lifecycle.Contact us at xcmotors@163.com to discuss your specific needs and discover how we can enhance your industrial processes today.