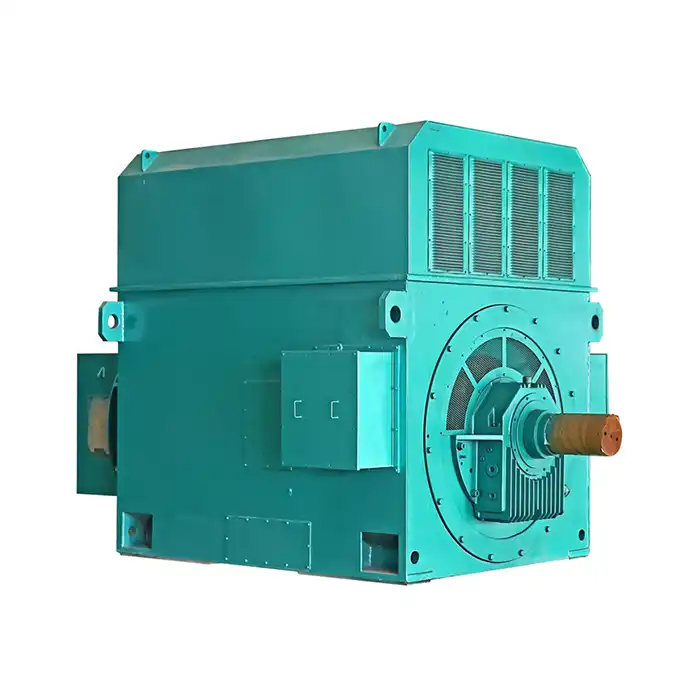

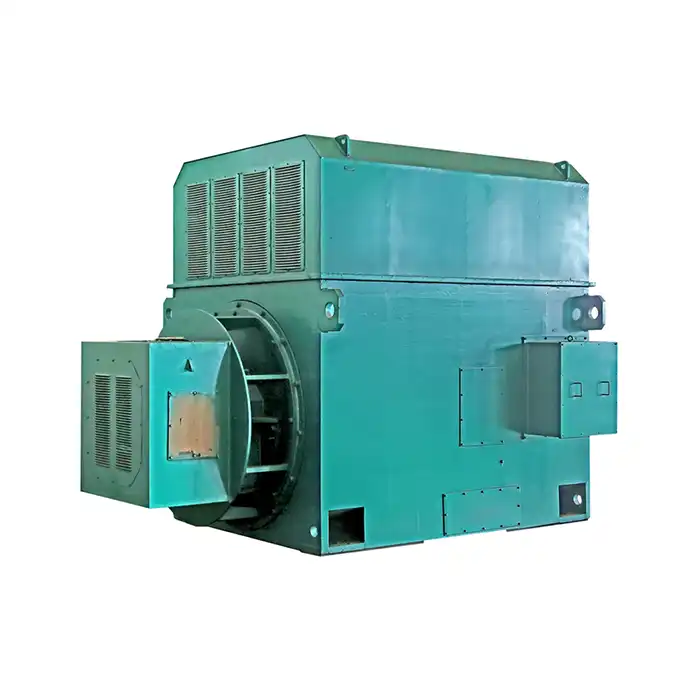

Wound Rotor Induction Motors

Protection level:IP54

Voltage range:3000V±5%,3300V±5%,6000V±5%,6600V±5%,10000V±5%,11000V±5%

Power range:200-4500 kW

Application:hoist, rolling mill, wire drawing machine.

Advantage:low noise, small vibration, reliable performance, easy installation and maintenance.

Standard: This series of products complies with JB/T10314.2-2002 standards.

Others: SKF, NSK, FAG bearings can be replaced according to customer requirements.

- Product Description

Wound Rotor Induction Motor Manufacturer and Supplier

As a leading manufacturer and supplier of Wound Rotor Induction Motors, Shaanxi Qihe Xicheng Electromechanical Equipment Co., Ltd. offers superior quality and performance. Our motors are designed to meet the demanding needs of various industries, providing high efficiency, low energy consumption, and stable power output. With over two decades of experience, we've perfected our products to deliver exceptional value and reliability.

Wound Rotor Induction Motor Description

Our Wound Rotor Induction Motors are engineered for superior performance, blending robust construction with cutting-edge technology. The wound rotor design allows for precise speed control and provides high starting torque, making it ideal for heavy-duty applications. These motors are designed to perform reliably in tough environments, such as mining, metallurgy, and heavy machinery industries. With their durable build and advanced features, our motors ensure consistent, efficient operation, even under the most demanding conditions, providing long-lasting and dependable performance for critical industrial tasks.

YRKK Product Specifications

| Power Range: | 200kW to 4500kW |

| Voltage: | 3kV to 11kV |

| Frequency: | 50Hz |

| Enclosure: | IP54/IP55 |

| Insulation Class: | F or H |

| Cooling Method: | IC611 |

Product Details

The Wound Rotor Induction Motors from XCMOTOR are designed with your needs in mind. Our motors feature:

- The motor offers high starting torque, ensuring powerful performance during initial startup, effectively handling heavy loads and demanding conditions.

- With smooth acceleration, the motor gradually ramps up speed, reducing mechanical stress and ensuring a stable and efficient operation.

- Adjustable speed control allows for precise tuning of motor speed, providing flexibility to meet specific operational requirements and enhance performance.

- The motor has excellent overload capacity, allowing it to handle unexpected increases in load without compromising its reliability or efficiency.

- Designed for low maintenance, the motor reduces downtime and operational costs, ensuring long-term reliability and minimizing the need for frequent service.

We employ a rigorous manufacturing process to ensure the highest quality:

- Design and engineering focus on creating efficient, durable motors, combining innovation and industry standards to meet specific application needs.

- Raw material selection ensures only the highest quality components are used, enhancing motor longevity, reliability, and performance under various conditions.

- Winding and assembly processes are executed with precision, ensuring optimal coil configurations and efficient integration of all motor components for maximum performance.

- Quality control and testing procedures rigorously check every motor, verifying that it meets performance, safety, and durability standards before reaching customers.

- Finishing and packaging are carefully carried out to protect the motor during transport, ensuring it arrives in perfect condition, ready for installation and use.

Application Scenarios

Our products are ideal for:

- Mining equipment

- Metallurgical machinery

- Cement plants

- Paper mills

- Water treatment facilities

Why Choose XCMOTOR?

- With over 20 a long time of involvement in engine fabricating, we have built a demonstrated track record of conveying solid, high-quality products.

- We guarantee quality affirmation through solid organizations with driving brands like ABB and Siemens, guaranteeing top-notch components and performance.

- Our engines offer customization, giving custom fitted arrangements outlined to meet your particular necessities, optimizing execution and effectiveness for your needs.

- We offer comprehensive back, giving master pre-sales and after-sales benefit to help with choice, establishment, and long-term maintenance.

- Our energy-efficient engines are planned to diminish operational costs by maximizing execution whereas minimizing vitality utilization, advertising long-term reserve funds.

FAQ

FAQ

Q: What's the main advantage of the products?

A: They offer high starting torque and precise speed control, making them ideal for heavy-duty applications.

Q: How long is the warranty on your products?

A: We offer a standard 12-month warranty, with extended options available.

Q: Can you provide custom products?

A: Absolutely! We specialize in tailoring our motors to meet your specific requirements.

Q: What's the lead time for the products?

A: Typical lead times range from 4-8 weeks, depending on specifications and quantity.

Q: Do you offer installation and maintenance services for your motors?

A: Yes, we provide comprehensive support, including installation guidance and maintenance services.

Contact us

At XCMOTOR, we're committed to powering your success with our high-quality Wound Rotor Induction Motors. Whether you're looking for standard models or custom solutions, our team is ready to assist you. Contact us today at xcmotors@163.com to discuss how we can meet your motor needs and drive your business forward.