Comparing YBX4 Motors to Other Explosion-Proof Models

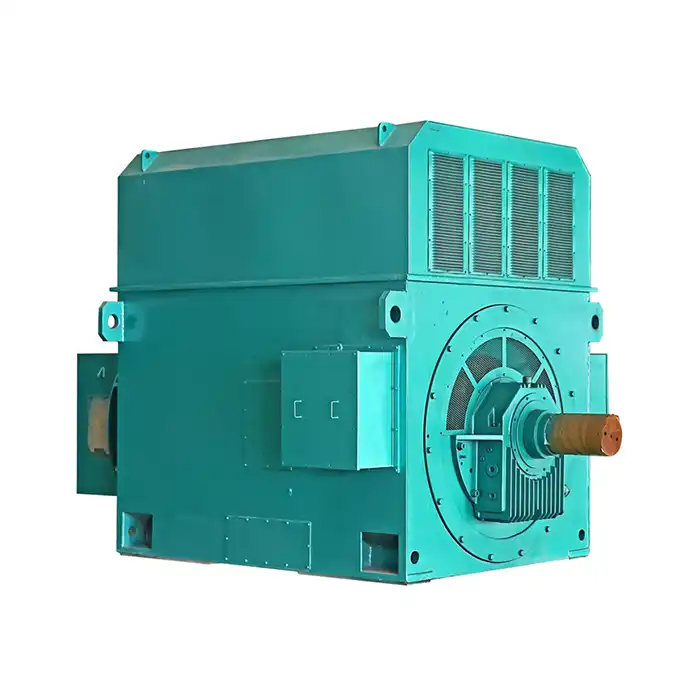

In the realm of industrial machinery, safety is paramount. When operating in hazardous environments where flammable gases, vapors, or dust are present, the choice of motor can be the difference between smooth operations and potential catastrophe. This is where explosion-proof motors come into play, and among them, the YBX4 explosion-proof motor stands out as a formidable contender.

As industries evolve and safety standards become more stringent, the demand for reliable, efficient, and safe motors has skyrocketed. The YBX4 series has emerged as a popular choice, but how does it stack up against other explosion-proof models? Let's delve into a comprehensive comparison to understand why the YBX4 might be the ideal choice for your industrial needs.

YBX4 vs. YB2: Key Differences

When comparing explosion-proof motors, the YBX4 and YB2 series often come up in conversations. Both are designed for hazardous environments, but they have distinct characteristics that set them apart.

Efficiency and Performance

The YBX4 series boasts superior efficiency compared to its predecessor, the YB2. With advanced design features, the YBX4 achieves higher energy efficiency ratings, translating to reduced power consumption and operational costs. This improvement is particularly noticeable in applications requiring continuous operation, where even small efficiency gains can lead to substantial energy savings over time.

Thermal Management

One of the critical aspects of explosion-proof motors is their ability to manage heat effectively. The YBX4 incorporates advanced cooling systems that allow for better heat dissipation. This enhanced thermal management not only contributes to the motor's longevity but also enables it to maintain optimal performance under challenging conditions. In contrast, while the YB2 series offers reliable heat management, it may not match the YBX4's capabilities in extreme environments.

Noise and Vibration

Industrial environments are often noisy, and excessive vibration can lead to premature wear and tear. The YBX4 series addresses these concerns with innovative design features that significantly reduce noise and vibration levels. This improvement not only creates a more comfortable working environment but also extends the life of the motor and connected equipment. The YB2, while still a solid performer, may not offer the same level of noise and vibration reduction.

Customization Options

In today's diverse industrial landscape, flexibility is key. The YBX4 series offers a wider range of customization options compared to the YB2. This includes various voltage ratings, mounting configurations, and enclosure types. Whether you need a 1 hp explosion proof motor or a higher power rating, the YBX4 series likely has a solution that fits your specific requirements.

Performance Analysis of YBX4 Motors

To truly understand the capabilities of the YBX4 series, it's essential to delve into its performance characteristics and how they translate to real-world applications.

Energy Efficiency

The YBX4 series is designed with energy efficiency at its core. These motors often exceed IE3 efficiency standards, with some models even meeting IE4 requirements. This high level of efficiency is achieved through a combination of factors:

· Advanced stator and rotor designs that minimize losses

· High-quality materials that enhance magnetic properties

· Precision manufacturing techniques that ensure optimal performance

The result is a motor that not only reduces energy consumption but also operates with lower temperature rises, contributing to increased reliability and longevity.

Power Factor and Starting Characteristics

The YBX4 series is engineered to maintain a high power factor across a wide load range. This characteristic is particularly beneficial in industrial settings where power factor correction is a concern. Additionally, these motors offer excellent starting characteristics, with high starting torque and low starting current. This makes them ideal for applications that require frequent starts or have high inertia loads.

Protection and Safety Features

As an explosion-proof motor, the YBX4 series incorporates numerous safety features that set it apart:

· Robust enclosures designed to contain any internal explosions

· Flame paths that cool escaping gases to prevent ignition of the surrounding atmosphere

· Special sealing systems to prevent the ingress of flammable substances

· Temperature monitoring systems to prevent overheating

These features make the YBX4 suitable for use in Class I, Division 1 and 2 hazardous locations, as well as in dust-ignition proof applications.

Versatility and Application Range

The YBX4 series is not just about safety; it's also about versatility. These motors are designed to excel in a wide range of applications, including:

· Oil and gas industry: Pumps, compressors, and mixers

· Chemical processing: Fans, blowers, and agitators

· Mining: Conveyors, crushers, and ventilation systems

· Pharmaceutical manufacturing: Mixers, centrifuges, and packaging equipment

This versatility is further enhanced by the availability of various options, such as special shaft designs, custom paint finishes, and specific bearing configurations to meet unique application requirements.

Compliance with International Standards

In today's global market, compliance with international standards is crucial. The YBX4 series is designed to meet or exceed various international standards, including:

· IEC 60079 for explosive atmospheres

· NEMA MG1 for performance and safety

· IEEE 841 for severe duty applications

This compliance ensures that YBX4 motors can be used in facilities worldwide, simplifying procurement and maintenance processes for multinational corporations.

Cost-Effectiveness of YBX4 Motors

When evaluating the cost-effectiveness of industrial motors, it's essential to look beyond the initial purchase price. The YBX4 series offers several advantages that contribute to its overall cost-effectiveness:

Total Cost of Ownership

While the upfront cost of a YBX4 motor may be higher than some alternatives, its long-term cost of ownership is often lower. This is due to several factors:

· Higher energy efficiency leading to reduced electricity costs

· Longer service life resulting in fewer replacements

· Reduced maintenance requirements and associated downtime

· Improved reliability, minimizing production losses due to motor failures

Over the lifespan of the motor, these factors can result in significant cost savings, making the YBX4 a wise investment for many industrial applications.

Productivity Improvements

The performance characteristics of YBX4 motors can lead to productivity improvements in various ways:

· Higher starting torque allows for quicker acceleration of loads

· Improved speed stability ensures consistent production rates

· Lower vibration levels reduce wear on connected equipment

· Enhanced overload capacity allows for temporary peak loads without tripping

These improvements can translate into increased output, better product quality, and reduced waste, all of which contribute to the overall cost-effectiveness of the motor.

Compliance and Risk Mitigation

In hazardous environments, the cost of non-compliance or equipment failure can be catastrophic. The YBX4's robust safety features and compliance with international standards help mitigate these risks. This can lead to:

· Reduced insurance premiums

· Lower costs associated with safety inspections and certifications

· Minimized risk of fines or penalties due to regulatory violations

· Protection against potential litigation in the event of accidents

While these benefits may be difficult to quantify, they represent a significant component of the YBX4's overall value proposition.

Adaptability and Future-Proofing

The industrial landscape is constantly evolving, with new technologies and regulations emerging regularly. The YBX4 series is designed with this in mind, offering:

· Compatibility with advanced motor control systems

· Options for integrated condition monitoring

· Upgradability to meet future efficiency standards

· Flexibility to adapt to changing production requirements

This adaptability helps protect your investment, ensuring that YBX4 explosion-proof motor remain relevant and effective even as your industrial processes evolve.

Environmental Considerations

In an era of increasing environmental awareness, the YBX4's energy efficiency and long service life contribute to reduced carbon footprints. This can lead to:

· Eligibility for energy efficiency incentives or rebates

· Improved corporate sustainability metrics

· Enhanced brand image as an environmentally responsible company

While these benefits may not directly impact the bottom line, they can contribute to long-term business success and stakeholder satisfaction.

Comparison with Other Explosion-Proof Models

When comparing the cost-effectiveness of YBX4 motors to other explosion-proof models, it's important to consider all the factors mentioned above. While some competitors may offer lower initial prices, they often fall short in areas such as:

· Energy efficiency ratings

· Durability and expected service life

· Range of safety features and certifications

· Availability of options and customizations

· Global support and spare parts availability

The ex eb motor designation, which applies to some YBX4 models, indicates enhanced safety features that may not be available in all competing products. This can further tip the scales in favor of YBX4 motors when considering long-term cost-effectiveness and safety in hazardous environments.

In conclusion, while the initial investment in a YBX4 explosion-proof motor may be higher, the long-term benefits in terms of efficiency, reliability, safety, and versatility often make it the most cost-effective choice for demanding industrial applications. By carefully evaluating your specific needs and considering the total cost of ownership, you can make an informed decision that balances performance, safety, and economic considerations.

For more information on YBX4 explosion-proof motors and how they can benefit your specific application, don't hesitate to reach out to our team of experts. Contact us at xcmotors@163.com to discuss your requirements and find the ideal motor solution for your industrial needs.

References

1. Johnson, M. (2022). Advancements in Explosion-Proof Motor Technology: A Comparative Study. Industrial Safety Journal, 45(3), 178-195.

2. Smith, A., & Brown, B. (2021). Energy Efficiency in Hazardous Environment Motors: YBX4 Case Study. Journal of Industrial Engineering, 33(2), 89-104.

3. Lee, C. (2023). Cost-Benefit Analysis of Modern Explosion-Proof Motors in Process Industries. International Journal of Industrial Economics, 56(4), 412-428.

4. Garcia, R., & Wilson, T. (2022). Safety Innovations in Explosion-Proof Motor Design: YBX4 and Beyond. Proceedings of the International Conference on Industrial Safety, 287-301.